WE USE COOKIES TO MAKE USING THE SITE CONVENIENT

ANNUAL SUBSCRIPTION

hyper DENT 10

BASIC

PROFESSIONAL

CUSTOMISED SECOND TIER MENU

OPTIMISATION OF THE WORKFLOW DUE TO THE CLARITY OF THE INTERFACE

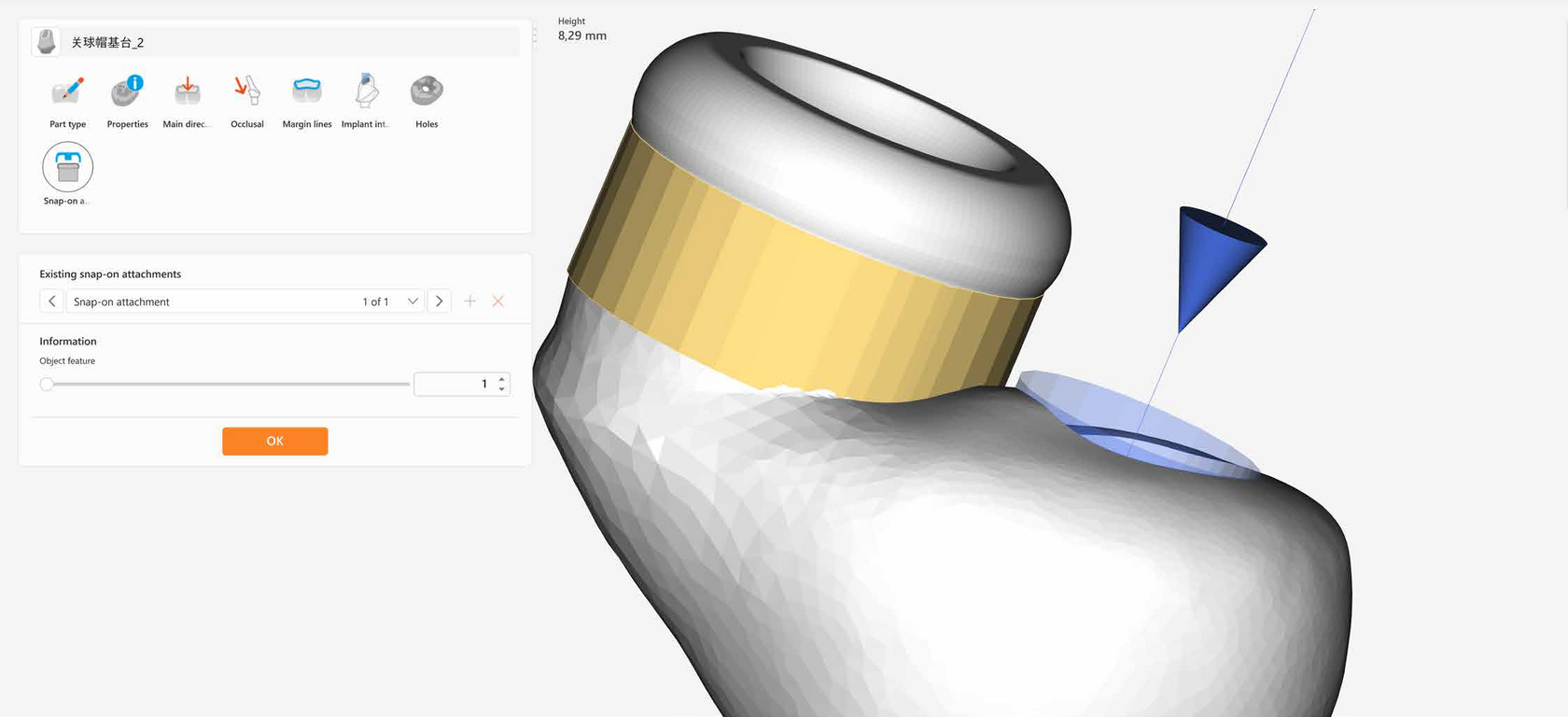

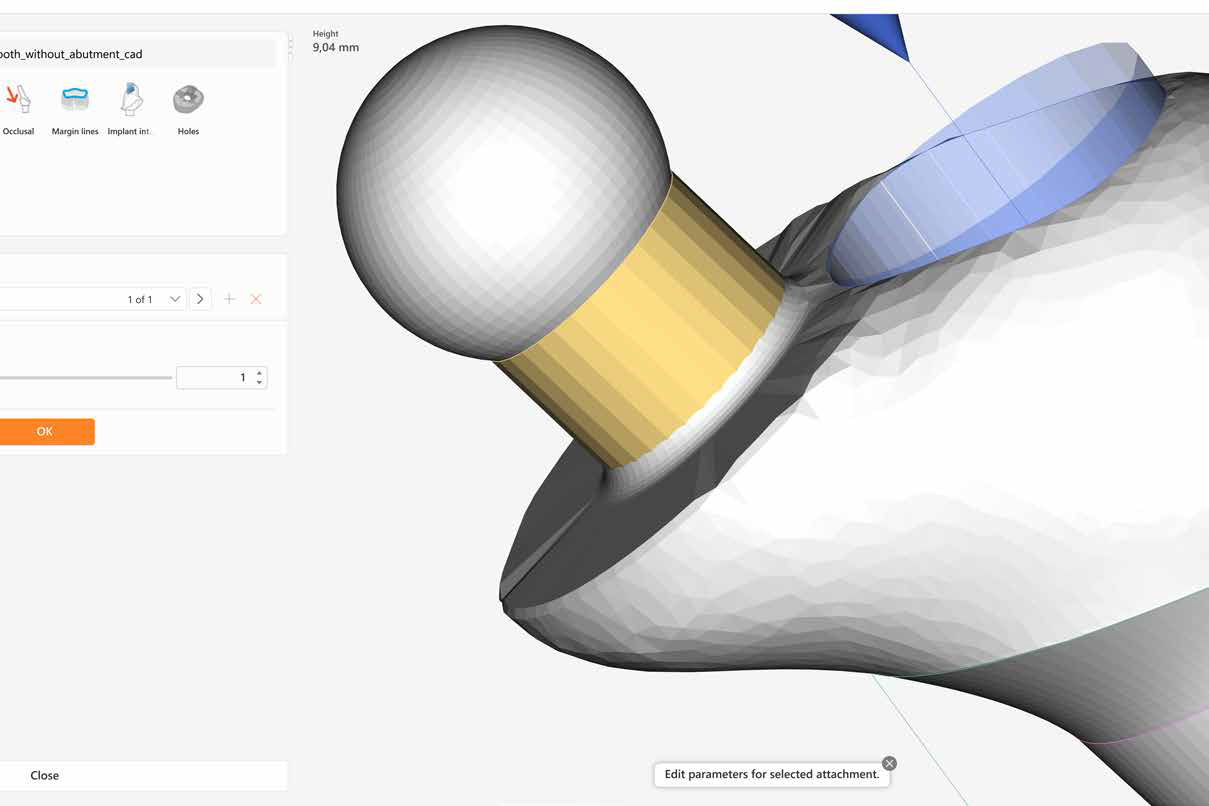

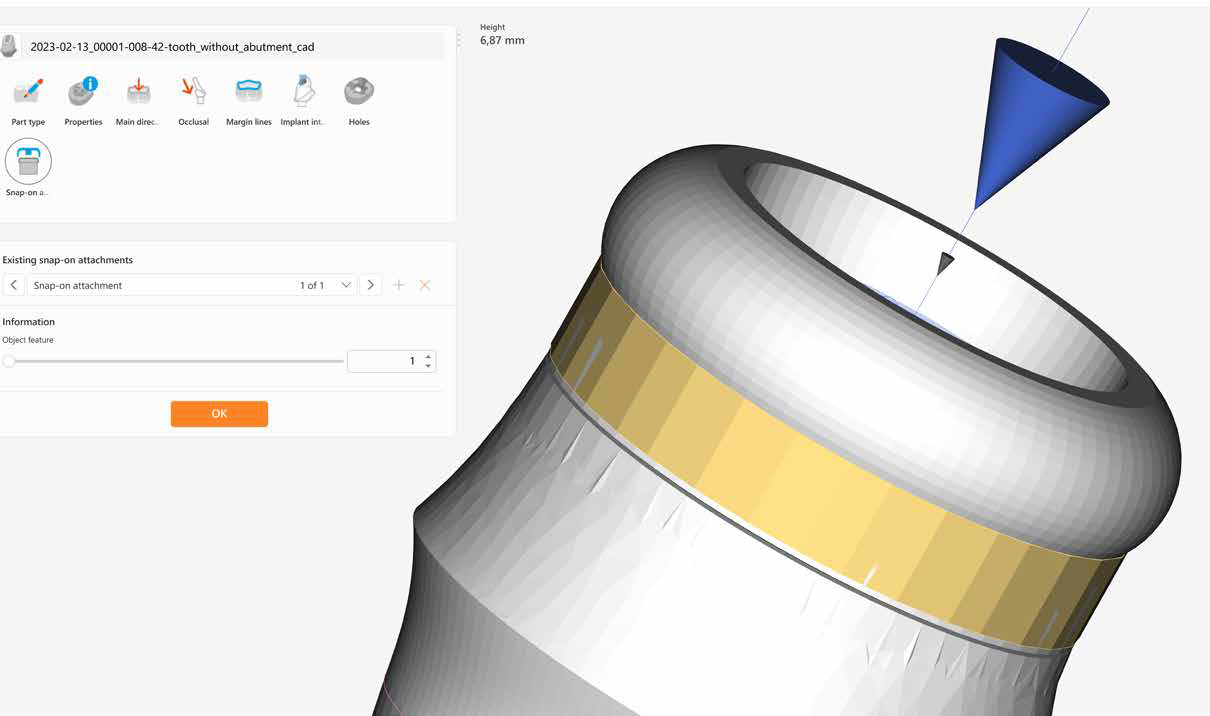

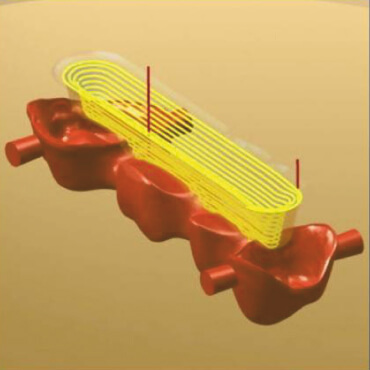

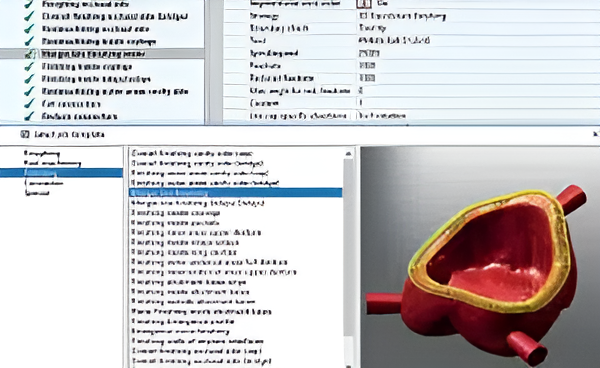

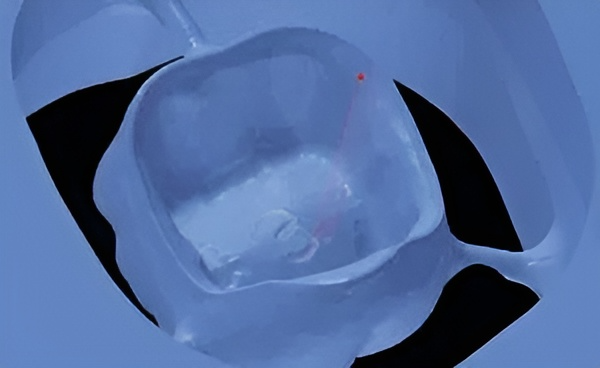

SNAP-ON ATTACHMENTS WITH UNDERCUT MACHINING

NEW TOOLPATH AND IDENTIFICATION FEATURES WERE DEVELOPED TO ACCURATELY MACHINE UNDERCUT WITH T-SLOT OR LOLLIPOP TOOL, LIKE FOR SNAP-ON ATTACHMENT

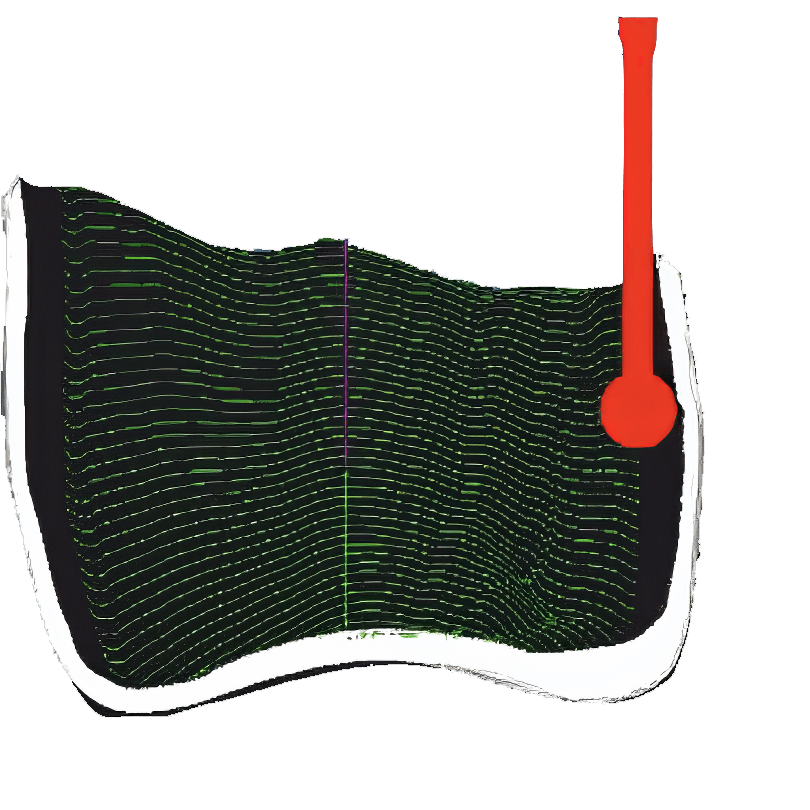

THE CURRENT VIEW AND ORIENTATION ARE INDICATED BY SIGNS AND COLOURS

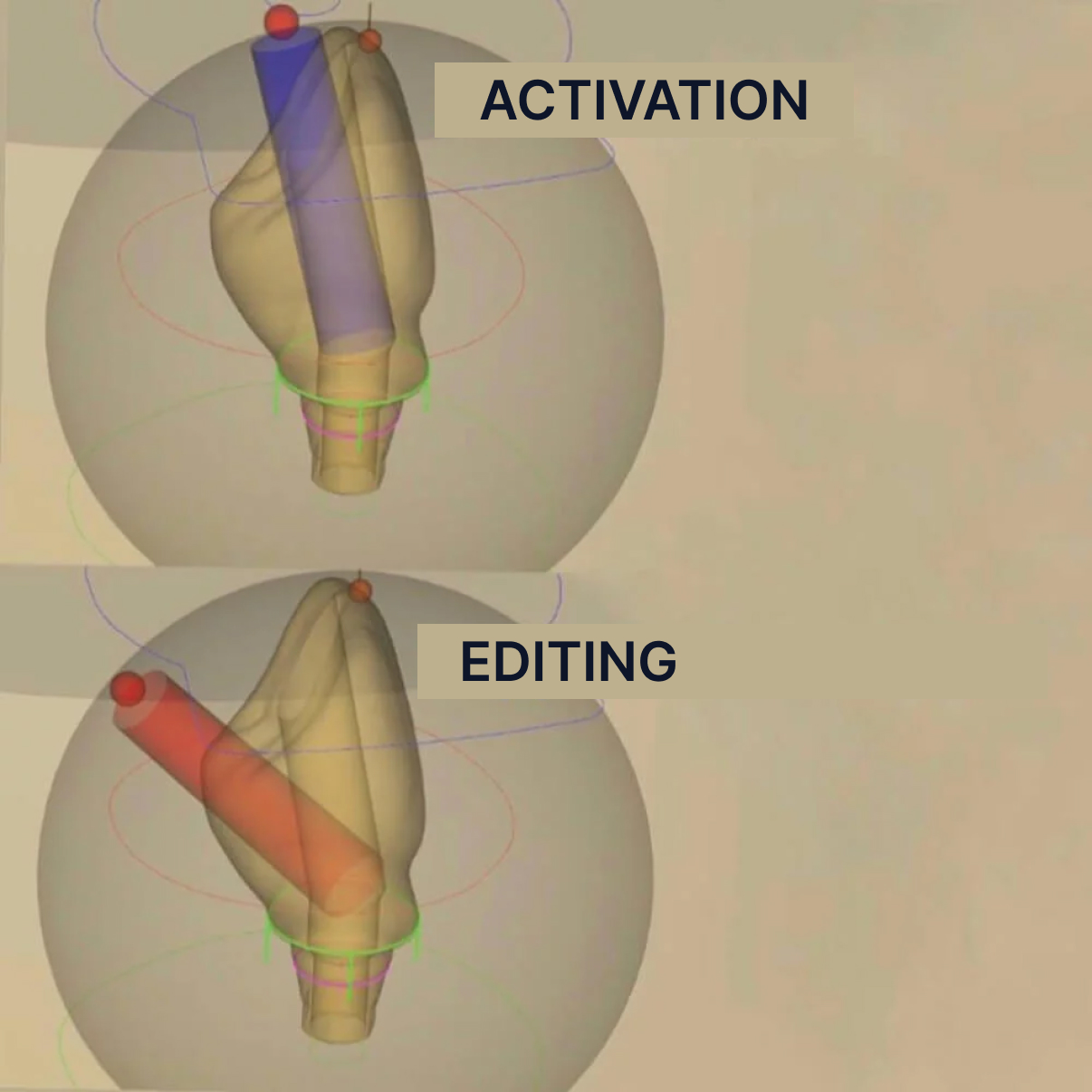

EDITING OF ANGLED SCREW CHANNELS

hyper DENT

PowerMilling

PowerMilling

TIME SAVING BY COMBINING ROUGHING AND FINISHING INTO A SINGLE MILLING JOB

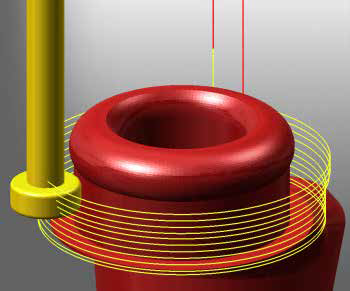

LOLLIPOP TOOLS SUPPORT

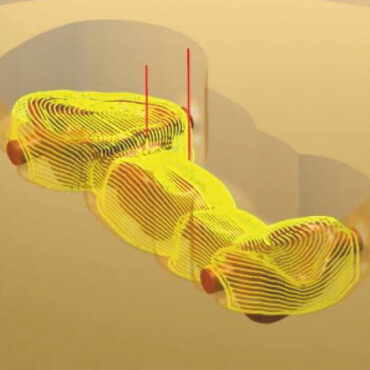

CREATING SINTER FRAME/STABILISER PROFILES

hyper DENT

AT THE FOREFRONT OF DENTAL ENGINEERING

hyper DENT — IT IS THE LEADING SOFTWARE IN THE DENTAL MARKET OF CAM TECHNOLOGIES

COMPLETE COVERAGE OF THE PRODUCTION PROCESS WITH A SINGLE SOFTWARE

COMPLETE COVERAGE OF THE PRODUCTION PROCESS WITH A SINGLE SOFTWARE

SIMPLE AND INTUITIVE HANDLING

MAXIMUM ACCURACY AND TIME EFFICIENCY

FLEXIBLE ADDITION OF FUNCTIONS

MAXIMUM FREEDOM IN CREATING STRATEGIES

HYBRID PRODUCTION AND ALL-IN-ONE MILLING

AUTOMATIC MEASUREMENT FOR THE MILLING PROCESS (HYBRID PRODUCTION)

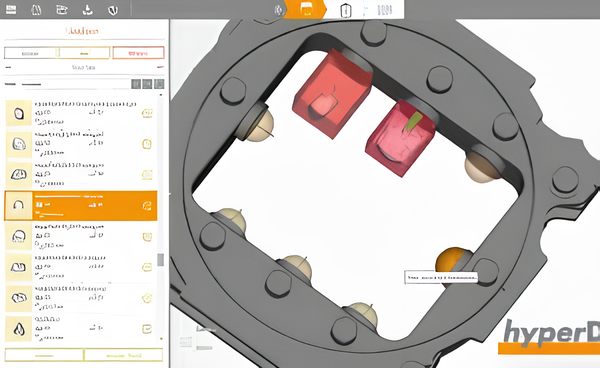

AUTOMATIC RECOGNITION OF DESIGNS USING IDENTIFICATION TAGS

CONTINUOUS IMPROVEMENT AND DEVELOPMENT OF SOFTWARE

OPTIMUM SURFACE FINISH THANKS TO PROVEN TOOLS PATHS

+ SOLID STATE SIMULATION

+ CUSTOMISED STRATEGIES

+ SIMPLE AND INTUITIVE USER INTERFACE IN WHICH AN EXPERIENCED USER CAN CREATE AND MODIFY PROCESSING STRATEGIES

+ AUTOMATIC AND MANUAL CHANNEL DETECTION

+ ANGULATED SCREW CHANNEL MILLING

+ OPTIMISED MILLING WITH T-SLOT (SHAPED) TOOLS

hyper DENT ANGULED SCREW CHANNELS

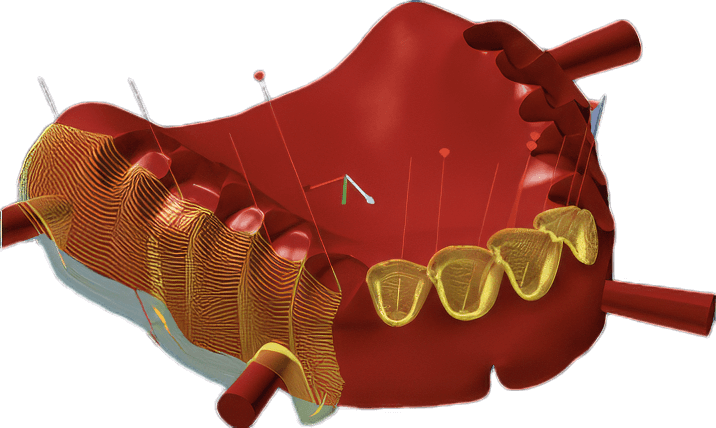

THE hyper DENT HYBRID MODULE ENABLES THE COMBINATION OF ADDITIVE AND SUBTRACTIVE TECHNOLOGIES IN A SINGLE WORKFLOW

HYBRID PRODUCTION OF DENTAL CONSTRUCTIONS

UNDERUTS AND USER-DEFINED AREAS

USER INTERFACE

PRODUCTION OF REMOVIBLE DENTURES

hyper DENT LITE STRATEGIES MODULE

THIS FEATURE ALLOWS USERS TO MAKE MINOR ADJUSTMENTS ON THEIR OWN WITHOUT REQUIRING THE FULL VERSION OF THE STRATEGY MODULE

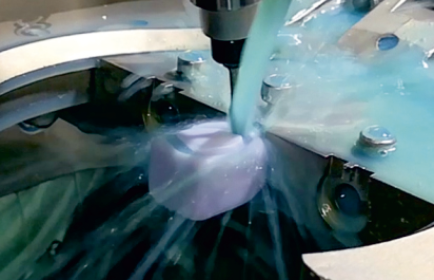

GLASS-CERAMIC GRINDING

THE GRINDING MODULE ENSURES OPTIMUM GRINDING OF GLASS-CERAMIC USING SPECIAL STRATEGIES FOR CREATING TOOL PATHS

BASIC FUNCTIONS

SMART hyper DENT SELECTION AUTOMATICALLY DETERMINES THE BLANKS FOR PROCESSING AND OFFERS THEM IN A WINDOW, INCLUDING ALL AVAILABLE PARAMETERS SUCH A SIZE AND MATERIAL TYPE

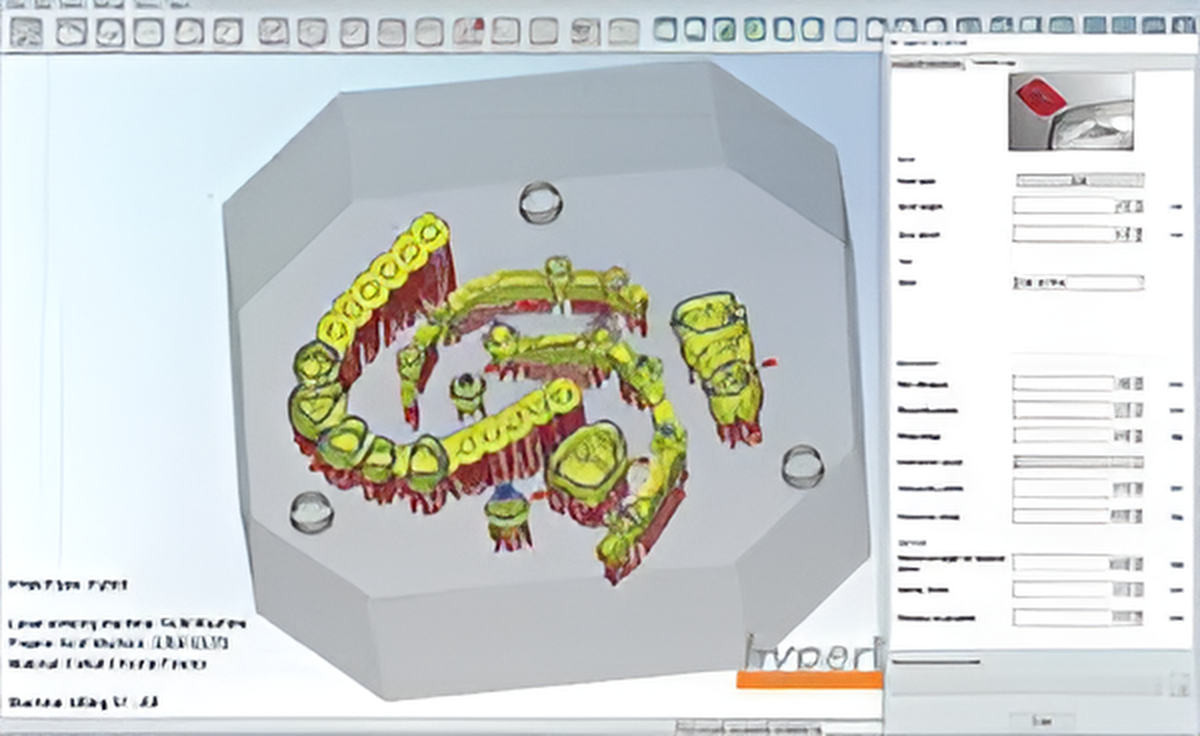

AUTOMATIC NESTING AND CONNECTORS SETTING

+ Optimum positioning of construction

+ Automatic tilting or rotating of the structure according to the machine's mechanical capabilities

+ Automatic installation of the connectors

HOLES

MILLING

MILLING

MACHINING OF ANY POSSIBLE HOLES WITH THE AVAILABLE MACHINING CYCLES

CONNECTOR AND SINTER FRAME

CONNECTOR AND SINTER FRAME PROFILES FOR EACH CONSTRUCTION WITH SPECIAL REQUIREMENTS.

INDIVIDUAL EDITING OF THE SHAPE AND POSITION OF THE CONNECTOR AND SINTER FRAME.

INDIVIDUAL EDITING OF THE SHAPE AND POSITION OF THE CONNECTOR AND SINTER FRAME.

BLANK TYPE FILTER

THE AUTOMATIC SELECTION OF THE BLANK REQUIRED FOR MILLING TAKES INTO ACCOUNT ALL KNOWN PARAMETERS OF THE MATERIAL, THE MACHINE, THE DIMENSIONS OF THE STRUCTURE.

THE DIALOGUE WINDOW WILL SHOW ONLY THE REQUIRED BLANKS, WHICH WILL MAKE THE SELECTION MUCH EASIER.

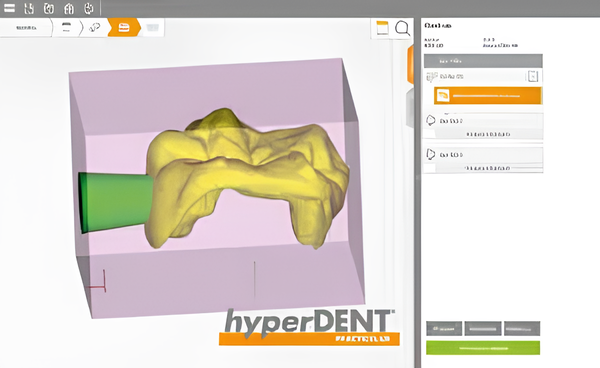

AUTOMATIC TILTING AND POSITIONING

THE STRUCTURE IS LOADED INTO THE BLANK AND TILTED ACCORDING TO THE MACHINE SETTINGS AND CAPABILITIES, AND THEN TILTED ACCORDING TO THE SELECTED STRATEGY.

THIS AUTOMATION GUARANTEES MILLING SAFETY.

MULTIPLE INSTANCES IN MULTIPLE WINDOWS

SIMULTANEOUS CALCULATION AND PREPARATION OF SEVERAL PROJECTS

ENGRAVING

ENGRAVING OF THE STRUCTURES AFTER PRODUCTION SIMPLIFIES THE SUBSEQUENT IDENTIFICATION AND DISTRIBUTION OF THE STRUCTURES

CREATING ENGRAVING PROFILES DEPENDING ON THE MATERIAL

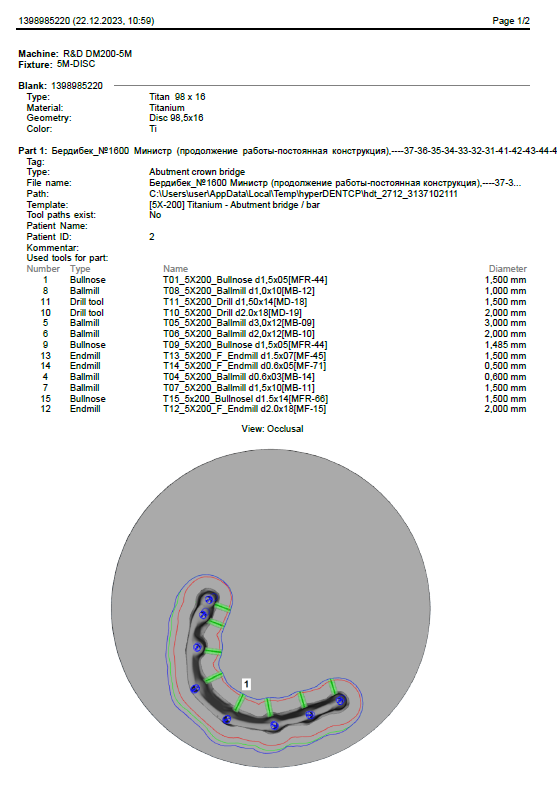

PROJECT DOCUMENT

+ PDF FILE AND SCREENSHOT ARE CREATED

+ ESTIMATED MACHINING TIME

+ BLANK TYPE

+ TOOL INFORMATION

CALL and Messengers

Write

CONTACTS

CONTACTS

CALL and Messengers

Write

RUSSIA

St Petersburg

Moscow

Kazan

Naberezhnye Chelny

Ekaterinburg

Krasnodar

Nyagan

Novosibirsk

Tomsk

Surgut

Chelyabinsk

Maloyaroslavets

Derbent

Vladivostok

Moscow

Kazan

Naberezhnye Chelny

Ekaterinburg

Krasnodar

Nyagan

Novosibirsk

Tomsk

Surgut

Chelyabinsk

Maloyaroslavets

Derbent

Vladivostok

ARMENIA

Yerevan

Vanadzor

Gyumri

Vanadzor

Gyumri

GEORGIA

Tbilisi

KAZAKHSTAN

Astana

Aktobe

Almaty

Shymkent

Aktobe

Almaty

Shymkent

MOLDOVA

Chisinau

LITHUANIA

Vilnius

Kaunas

Vilkaviškas

Kaunas

Vilkaviškas

HUNGARY

Budapest

UKRAINE

Kiev

Odessa

Odessa

INDIA

Mumbai

TURKEY

Istanbul

Kayseri

Ankara

Kayseri

Ankara

SPAIN

Barcelona

Torrevieja

Torrevieja

SWEDEN

Stockholm

GERMANY

Munche

POLAND

Warsaw

Otwock

Krakow

Szczecin

Katowice

Gliwice

Otwock

Krakow

Szczecin

Katowice

Gliwice